Pump Selection for Solar Hot Water Systems

I’ve been having some conversations with a few engineers about how to properly select pumps for large solar hot water systems. The pumps used in our Fluid Handling Systems are selected from major manufacturers, such as TACO and Bell & Gossett. Each pump is chosen for the particular characteristics needed for solar thermal collector operation. In particular, solar hot water pumps require high head and relatively low flow.

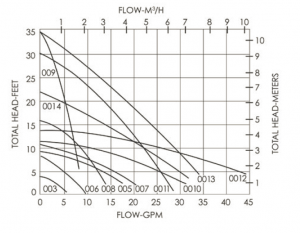

I have been using TACO pumps in since 1977. The 00 series of pumps is well suited to the high head, low flow requirements of solar thermal systems.

For our recent GTCC job, I have chosen the 0013 pump. This particular pump is called a cartridge circulator, meaning that the water it pumps acts like the coolant and lubricant inside the pump. Maintenance consists of replacing the cartridge inside.

TACO has guaranteed the operation of its line of pumps in solar water heater applications since the ’70s and their performance has exceeded the guarantee.

We have received information of our solar water heating systems in continuous operation for 25 years and are proud of our rugged design. We actually have a 25 year old system in our shop that we replaced this winter. It is in perfect working condition. The TACO 009 pump is still in working order!

As a manufacturer, Holocene very carefully controls the quality and performance of our products. The Fluid Handling Systems we manufacture are integrated packages with components that work together for durability and high efficiency.

Dr. Ben

How do you select a pump for a solar hot water system?(calculations,selecting model of pump,software,etc)

Alireza,

Sorry to be so late answering you. To determine the proper pump for a drain back project, we have to know two things – the head, and the flow rate.

The head is the maximum height the water must be pumped. That is the height of the water in the tank (not the floor) up to the highest point on the collectors. Then we add a little fudge factor for safety, say 10 ft.

The flow rate comes from the number of collectors and the recommended flow rate per collector. I use 0.025 gpm/ft2 of collector area.

So, if we have a 30 ft head and 400 ft2 of collectors (10 gpm), we can now start looking for a pump. From previous knowledge, I know one of the TACO 00 series or 2400 series will do this job. The literature for these pumps has curves that show the performance of each model. I look at the gpm axis, then go up to the head I need and select that pump.

For bigger commercial jobs, say 50 gpm at 150 ft. it is more difficult. For this task, I go to a major pump manufacturer’s website and use their calculator. You enter in the head and flow rate and sometimes the desired pump efficiency, and the calculator comes back with a series of pumps that could do the job. Usually, the impeller must be trimmed at the manufacturer to match what you entered. This is why there are no specific curves for each pump. There are general curves, but the pumps are trimmed for the exact requirements you enter.

If I don’t like what I see on the commercial pumps, I send an email to my local pump rep and ask him to check for me. Sometimes, they have access to pumps and calculations that are not public.

I hope this helps.