One tank or two, sir?

The efficiency of a solar thermal system increases as the temperature of the water flowing through the collectors decreases. This is just basic physics. We don’t want the solar water to be any warmer than necessary at any given time. Systems that are designed and operate with this principle in mind will generate energy more efficiently.

For example, suppose a solar water heating system starts up in the morning with the solar storage tank at 70F. That means 70F water goes into the collectors to be heated. The solar collection efficiency can be as high as 60-65% at this temperature. If the water going to the collectors is 140F, the solar collection efficiency falls to about 30-40%.

Note that heating water from 70 to 80F requires exactly the same energy as heating water from 130 to 140F, so we want to use solar for the first low-temperature portion of heat input, not the last high-temperature portion.

That is why we always hook the solar into the cold water side of the conventional water heater. We can put a lot of heat into the coldest water at the highest efficiency. Roughly speaking, want the solar system to put the first 50% of the heat into the water and the electric element or gas burner to put in the last 50%.

With this as background, let’s compare the designs of the two most common types of solar water heaters in use today.

One Tank

Single-tank solar systems combine the solar storage tank with the conventional electric water heating tank in a single tank. The solar portion is on the bottom and the electric portion is on the top. Single-tank systems cannot incorporate gas water heaters because they heat from the bottom which destroys the solar efficiency. Generally, 50% of the volume is deemed to be “solar storage” and 50% is conventional storage. That means an 80 gallon single-tank system has 40 gallons of solar storage and 40 gallons of conventional storage. That is minimal solar storage.

The biggest challenge for single-tank systems is to prevent the electric heat from heating the solar part of the system and knocking down the solar efficiency. Single-tank design engineers spend most of their time trying to design baffles and port positions that minimize mixing of the electric heat down to the solar area. Of course, when they share the same body of water, they have to transfer heat.

Single-tank system can be very expensive. They are basically specialized water heaters with added components. They have lifetime of 7-10 years, just like a regular water heater, but replacing one is not cheap.

Single-tank solar water heaters have many components that are poorly insulated or not insulated at all. Pumps and site glasses, valves, expansion tanks, air vents, and pressure relief valves, are all items that waste heat to the surrounding air.

Two Tanks

A two-tank system avoids the inefficiencies of the single-tank system. However, most of them still have pumps, controls and valves exposed to the surrounding air to waste energy. The conventional water heater may still have a built in heat exchanger, which makes it a higher cost special tank with a lifetime of 7-10 years. Double-tank solar systems work very well with gas water heaters.

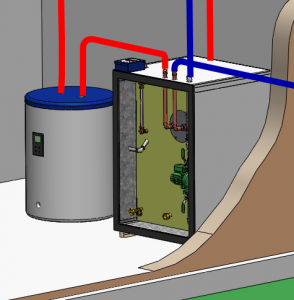

HoloTech solar storage tanks are true two-tank solar systems. The conventional water heater can be any conventional design, electric, gas, instantaneous, etc. No special heaters are required. Total separation is achieved between the solar energy and the conventional energy input to the water.

HoloTech solar storage tanks are true two-tank solar systems. The conventional water heater can be any conventional design, electric, gas, instantaneous, etc. No special heaters are required. Total separation is achieved between the solar energy and the conventional energy input to the water.

The HoloTech solar tank uses a proprietary design to maximize efficiency. All the operating components – the pump, DHW exchanger, site glass, drain valve, and collector pump are contained within an insulated cavity on the front of the tank. This means that all the heat from the pump goes into heating the water! In addition, no heat is wasted from exposed components. The only items outside the tank cavity are the water lines to the collector and to the conventional water heater.

The HoloTech design has no heat exchanger between the collectors and the tank. This means all the energy generated gets into the solar tank. Systems that have a heat exchanger between the collectors and tank transfer less of the energy collected into storage.

HoloTech solar water heaters have been in continuous operation for thirty years. The long life comes from 50% thicker tank metal with a harmless corrosion inhibitor to protect the steel and copper in the system. The potable water goes through a copper coil heat exchanger, which can be replaced without having to buy the whole system. The unit has a painted metal jacket with a door that is neat and attractive.

Finally, the 80 gallon version is shaped like a washing machine with a flat top. This means a 40 gallon conventional water heater can be placed on top, so the whole two-tank system takes up minimal floor space. An 80 gallon HoloTech tank with a 40 gallon water heater totals 120 gallons, giving far more storage volume than a single-tank 80 gallon system.

I’d love to hear your thoughts in the comment section,

Dr. Ben

I’ve been plumbing a Simple Drainback tank with standard gas hot water tanks using a thermosiphon design. This has proven to be an excellent proposition.

The design is elegantly simple. Simply set the conventional tank up on a 20′ stand so the cleanout of the standard tank is slightly above the inlet to the Simple Drainback heat exchanger. I set a “t” in that line, with cold water feed at that location. I also place a check valve between the “T” and the backup tank to prevent reverse thermosiphoning.

The balance of the plumbing is standard, with the heat exchanger pre-feeding the standard tank.

What we find is thermosiphon action effectively moves cold from the bottom of the gas backup tank into the heat exchanger, the water is heated and then passes up into the top of the backup tank. This extends storage, allows the collectors to run more efficiently, and does so without pumps or controls.

One note: We find evacuated tubes to be better for this application. I disagree with the notion that the SRCC efficiency curves correctly characterize evacuated tubes. The science used in testing is, in my opinion, based on a single irradiation point (high noon). In actuality, tubes run far hotter for longer periods of the day than flat plates. For thermosiphon design, tubes provide greater fluid heating, thus more effective thermosiphoning.